Stellantis Pro One announced the start of production of the Cargo Box BEV

Stellantis Pro One start of production of the Cargo Box BEV

Atessa, July 3, 2025 – Stellantis Pro One announces the start of production of the Cargo Box BEV, produced at the Italian Atessa (CH) plant, where Stellantis’ Large Vans (Citroën Relay, Fiat Professional Ducato, Peugeot Boxer and Vauxhall Movano) are manufactured. These brands consistently maintain leadership in the European LCV market, with a share exceeding 30%.

As the light commercial BEV with the highest capabilities on the market, the Cargo Box offers an exceptional cargo capacity of 18.3 m³, complemented by a spacious interior with dimensions of 4,230 mm in length, 2,032 mm in width, and 2,150 mm in height. It is based on the Battery Electric Chassis Cab version, delivering 410 Nm of maximum torque and a power of 200 kW (270 hp), paired with a 110 kWh battery, for a driving range of up to 323 km. Additionally, for customers needing extra cargo space, it will also be available in the L4 configuration, expanding the cargo volume to 20.5 m³ with an internal length of 4,500 mm and a height of 2,300 mm.

To further enhance the offering in the Large Van range, Stellantis Pro One is now introducing the 22-kW AC charging as standard. A complete charge can now be conveniently achieved overnight, ensuring the vehicle is ready for use at the start of the next working day. 22-kW AC charging provides a full recharge in just 6 hours, half the time compared to the previous 11-kW solution.

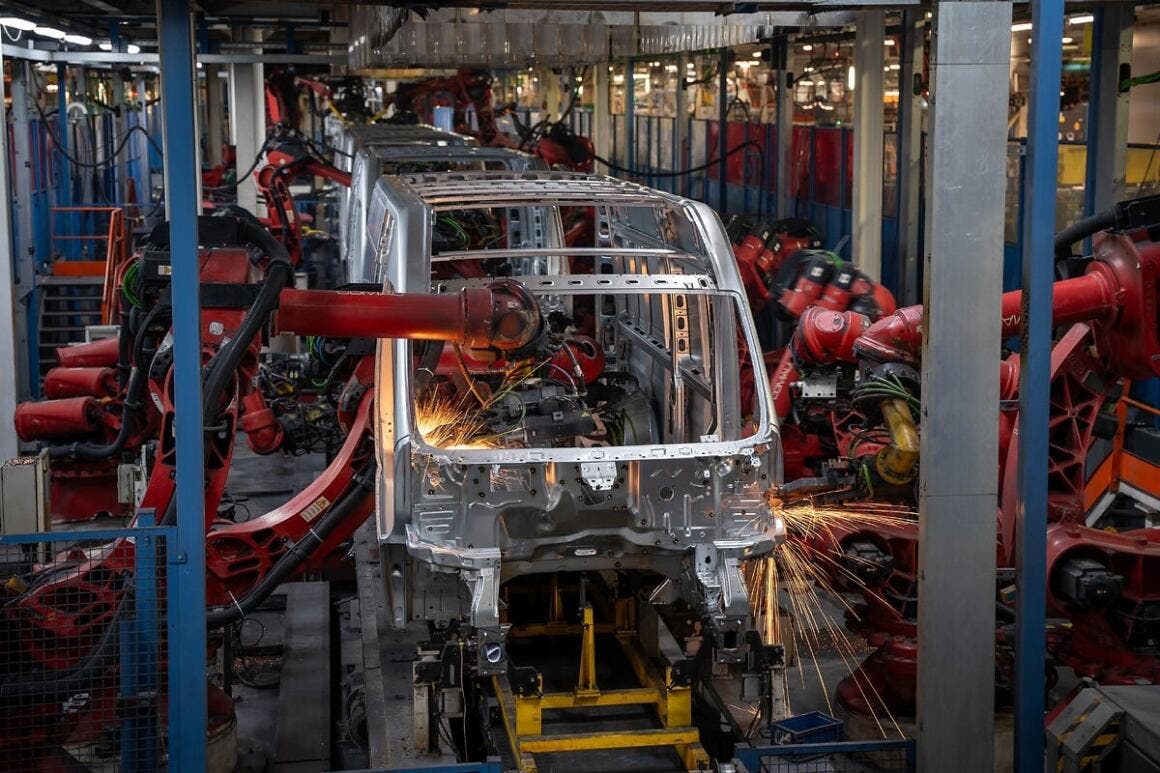

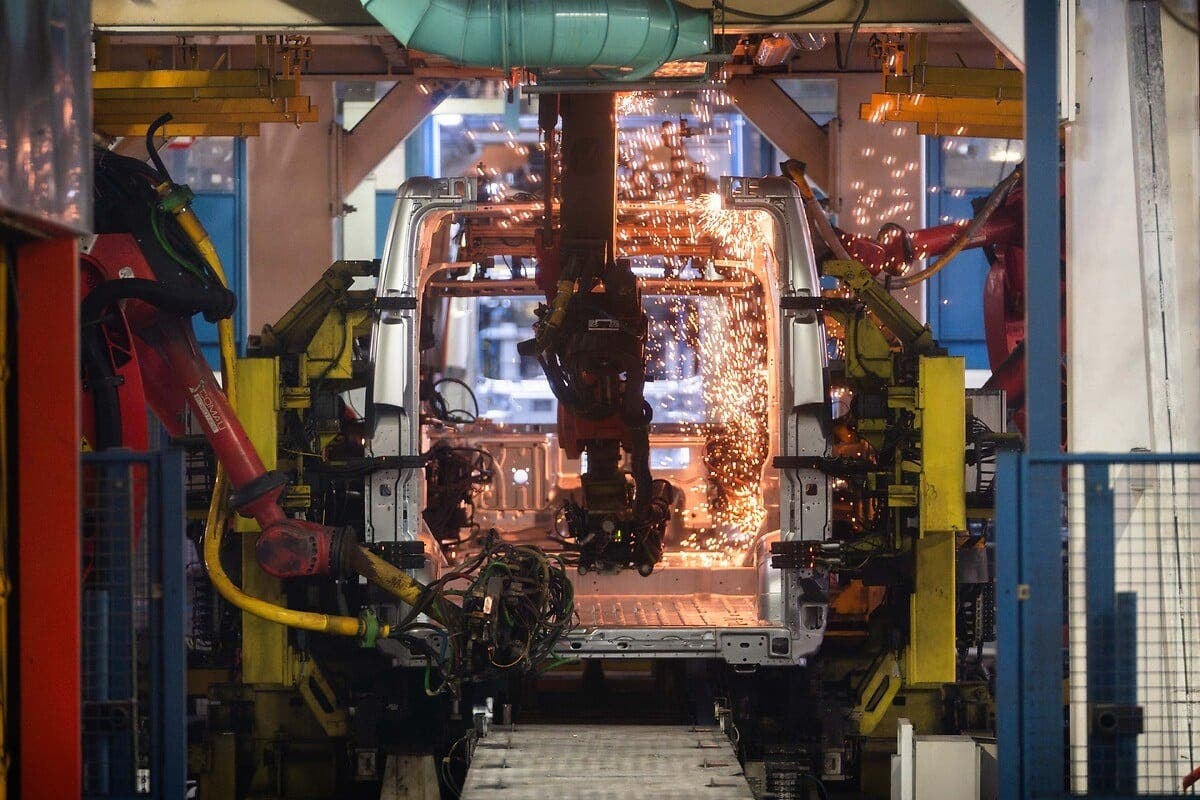

The Atessa plant, with over 1.2 million square meters of surface area, is not only the largest factory in Europe exclusively dedicated to light commercial vehicles but also a global benchmark, with 80% of production destined for export to 75 countries worldwide.

With 15 km of assembly line production, the largest body shop in the Stellantis galaxy and a constantly renewed paint shop to meet the latest energy and environmental sustainability criteria, Atessa can handle over 1,200 different types of configurations, from caravan bases to convertible vehicles to those intended for goods transport. With 14 engines, 4 types of transmission, over 300 options, and 8 van volumes, the plant constitutes a complete production ecosystem capable of offering over 2,500 different versions.

It is also one of the most advanced hubs for Stellantis CustomFit, an evolving conversion and customization program that now involves 50% of Stellantis Pro One CV production, but also includes integration with solutions developed in collaboration with a network of over 550 certified partners worldwide. This extensive network enables Stellantis to meet clients’ every professional requirements and to provide converted vehicles through the dealer network, to optimize delivery times and client experience.

In terms of performance, in 2024 Stellantis recorded a 25% increase in conversions with certified partners and doubled the number of customized units for large fleets made in-house, with 35% growth in sales of converted vehicles across Europe.

Anne Abboud, Head of Stellantis Pro One division, stated: “The launch of the Cargo Box BEV confirms the outstanding journey of this plant dedicated to proactively and quickly meeting the needs of our professional clients, according to the principles of efficiency, maximum quality, and time to market. Stellantis Pro One’s offering is unmatched in terms of range breadth and flexibility.”

Arnaud Leclerc, Global Head of Stellantis CustomFit, adds: “The direct production capacity of our plants in the CustomFit sector is integrated and expanded by a global network of 550 authorized partners who interact with our official network, thus ensuring an extremely widespread network of touchpoints. All fittings made by our partners also enjoy the same 2-year warranty coverage as vehicles coming directly from the factory.”

Another area of particular interest for Stellantis CustomFit is the realization of transformations for the Caravan and MotorHome (RV, Recreational Vehicles) sector, where Stellantis Pro One is once again the undisputed market leader. Leclerc continues: “We have been working in this market segment since 2006 and have never stopped innovating or interrupted our constant dialog with RV manufacturers, seeking the most practical and functional solutions alongside them. To prove this is one of the smartest innovations in this sector, we have defined it as “BacktoBack”: in practice, we have managed to connect two independent driving cabins, which can thus be moved as a single vehicle, with evident efficiencies in terms of costs, logistic and environmental footprint.”

A constant commitment to innovation and remaining at the forefront forms part of our mindset and everyday work. Always paying attention to our clients’ requirements, Stellantis Pro One is now introducing a full-electric version of its recreational vehicles.Leclerc continued, citing market data: “After all, Stellantis Pro One has sold over 2 million camper vans in the last 20 years, and 75% of the circulating segment is built on a Ducato base. It cannot be a coincidence that for 17 years running, the Ducato has been acknowledged as the Best Camper Van Base by as authoritative a publication in the field as the German magazine Promobil. There can be no better summary of what we do than our motto, “Fit for Mission,” as demonstrated by the BEV version. We are ready to launch a BEV line-up to meet the demands of our most attentive and discerning clients.