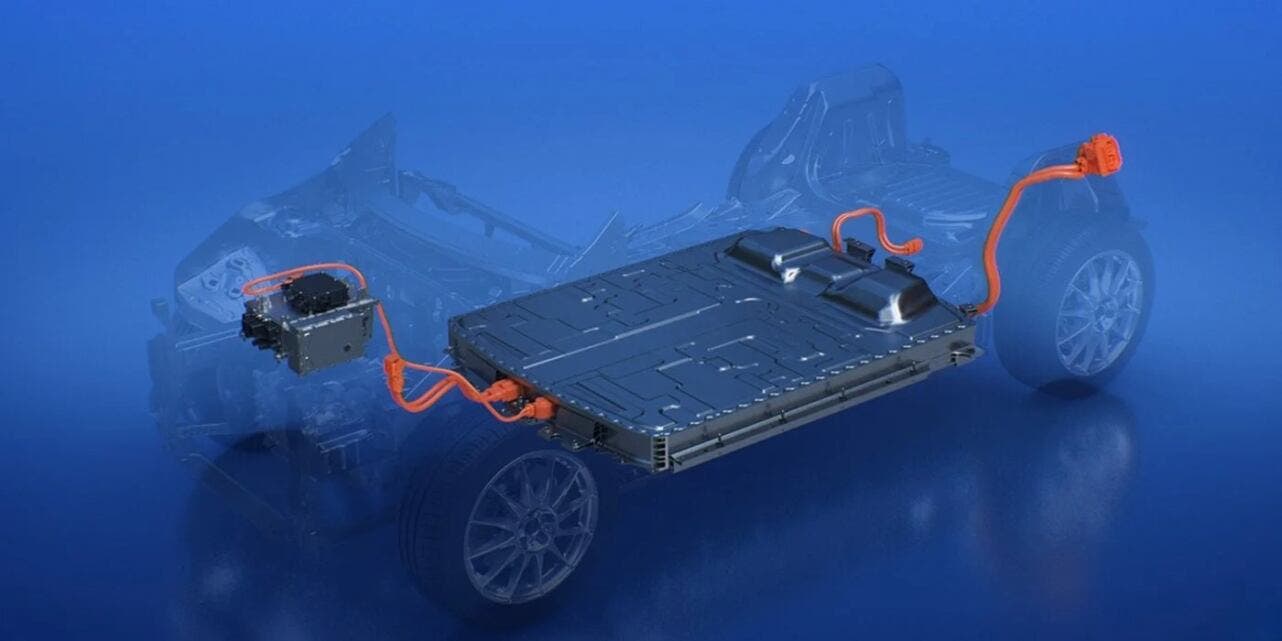

Despite the slowdown imposed in recent months on electric vehicles, Stellantis has not stopped working on technologies that could make battery-powered cars safer and more credible in the medium term. On the contrary. In recent hours, a development has caught the attention of industry insiders, following the filing of a new patent by the group led by Antonio Filosa.

The document focuses on one of the most sensitive issues in electric vehicles: battery safety. More specifically, Stellantis has patented an innovative system designed to counter thermal runaway, the chain reaction that can cause cells to overheat uncontrollably and, in the worst cases, lead to a battery fire.

Stellantis patents a new system to improve electric vehicle battery safety

MoparInsiders first reported the patent and described it as a proactive approach that differs from more traditional solutions. Instead of limiting damage once a failure has already occurred, Stellantis’ system acts before the situation escalates. It isolates the critical cell and prevents heat from spreading to the rest of the battery pack.

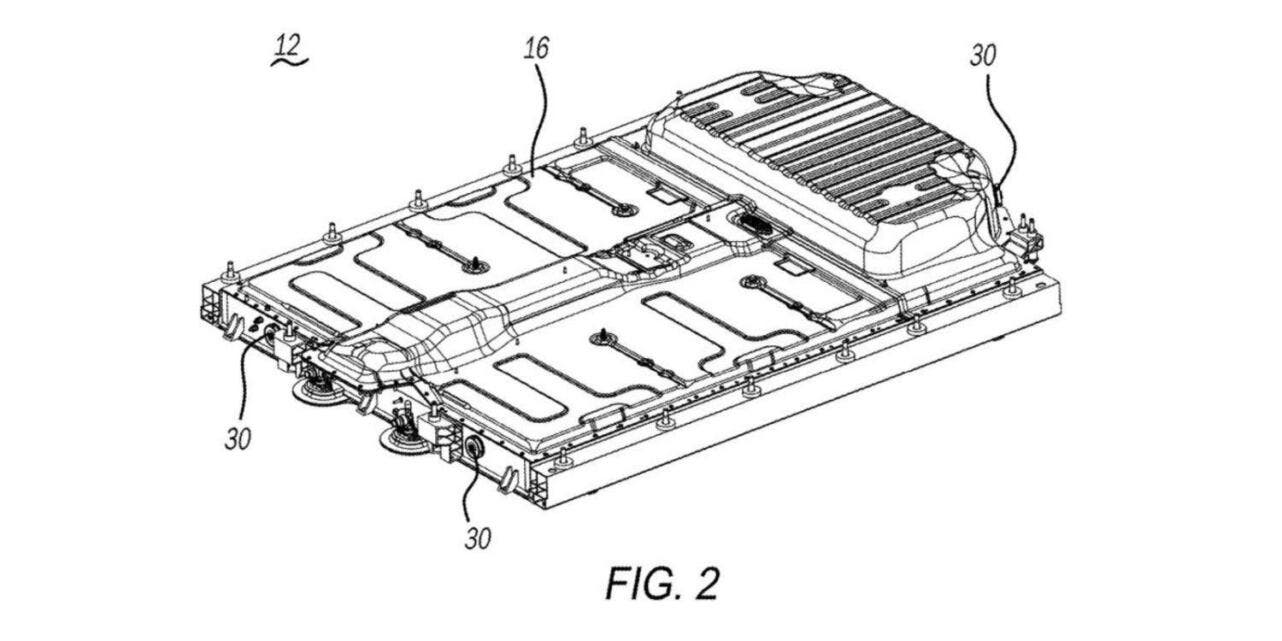

The concept is relatively straightforward, at least on paper. The battery integrates channels and ducts filled with a highly insulating foam. When sensors detect an abnormal temperature rise in a cell, the system activates and rapidly releases the foam into the affected area. As a result, the solution cools and separates the problematic zone from the rest of the pack. In this way, the chain reaction slows dramatically or stops altogether.

According to the patent, the battery pack does not differ significantly from conventional designs when viewed from the outside. However, it hides several safety-focused solutions inside. One of the most interesting features involves a flexible bladder made of polymer material and filled with a fire-retardant substance. Engineers position this bladder close to the cells and design it to rupture only in emergency situations.

Two sets of blades trigger the system. The first set punctures the bladder and releases the fire-suppressing agent. The second set acts on the cooling lines or heat sinks, allowing the foam to reach critical points quickly. In addition, the cooling lines use sealed sections that maintain pressure during normal operation but can be pierced easily when the system activates.

A controller manages the entire process. It connects to temperature sensors and integrates into the battery’s thermal management system. Under normal conditions, the device remains inactive and does not interfere with vehicle operation. It steps in only when the system detects a potentially dangerous scenario.

On paper, this solution appears both interesting and technically sophisticated. It remains unclear if and when Stellantis will move from the patent stage to mass production. However, the message is clear. Even during a more cautious phase for electric vehicles, Stellantis continues to invest in technologies that could significantly improve the safety and reliability of battery-powered cars.