The all-new 2.0-liter Hurricane 4 Turbo four-cylinder engine delivers power and torque comparable to a six-cylinder engine. SAE-certified power ratings include: 324 horsepower – 332 lb.-ft. of torque

Innovative turbulent jet ignition (TJI) technology promotes rapid and complete combustion for more power with less fuel and emissions. The variable geometry turbocharger generates increased power at lower engine speeds, with 90% of torque available from 2,600 to 5,600 rpm and 100% of torque from 3,000 to 4,500 rpm. Powerful and efficient: the Hurricane 4 Turbo uses 10% less fuel to deliver 20% more power than the current 2.0-liter DOHC I-4 engine.

2.0-liter Hurricane 4 Turbo

October 28, 2025, Auburn Hills, Michigan – Stellantis unveils the all-new 2.0-liter Hurricane 4 Turbo four-cylinder engine, combining advanced design and engineering innovation with high-performance combustion technology. This new engine generates more horsepower and torque than many engines of comparable size and dimensions, while delivering better fuel economy and lower emissions.

The power of the compact 2.0-liter Hurricane 4 Turbo—324 horsepower at 6,000 rpm and maximum torque of 480 Nm between 3,000 and 4,500 rpm—gives it the power it needs to confidently push vehicles of various sizes, from compact to large.

“The name Hurricane 4 Turbo is fitting because this engine is powerful, as the variable geometry turbocharger, high-performance combustion, and dual-fuel system deliver 162 horsepower per liter of displacement,” said Micky Bly, Stellantis senior vice president and head of global powertrain systems. “The clean design gives our customers a powerful, refined and smooth engine that consumes 10% less fuel to deliver 20% more power than our current 2.0-liter DOHC I-4.”

The first application for the Hurricane 4 Turbo is the 2026 Jeep® Grand Cherokee. The engine design includes flexibility for conventional, hybrid, and plug-in hybrid powertrains.

Proven combustion technology with proven performance

Fundamental to the Hurricane 4 Turbo’s combination of abundant power and benchmark fuel efficiency is the use of turbulent jet ignition (TJI) combustion technology, used in world-class racing engines.

The Hurricane 4 Turbo’s innovative TJI passive system uses a spark plug to ignite a small amount of fuel in a cup-shaped prechamber located above each cylinder. The burning fuel expands and is fed into the combustion chamber, triggering faster and more complete combustion of the air-fuel mixture, which results in better performance and improved fuel efficiency.

Stellantis engineers combine TJI combustion and turbocharging with a Miller cycle operating strategy that closes the intake valves early to optimize engine efficiency and reduce emissions. This allows the Hurricane 4 Turbo to use a 12:1 compression ratio that generates power without the risk of harmful engine detonation (pre-ignition) using regular gasoline (87 octane).

Each cylinder of the Hurricane 4 Turbo has two spark plugs, one for the TJI chamber and one for the combustion chamber. Ion detection is used to detect misfires.

Power and efficient performance

The Hurricane 4 Turbo uses both direct injection and high-pressure direct injection (350 bar/5,076 psi). The engine controller uses one of the two fuel systems or both in combination, depending on the engine status and driver demand:

Cold start: both fuel systems are active to promote rapid ignition of the catalytic converter

At idle and low loads: direct fuel injection is active to minimize noise, vibration, and harshness (NVH) and to reduce particulate emissions.

Typical power loads: both direct injection and direct injection systems are active with a variable ratio based on driver demand

Maximum power/maximum torque: both systems are active, with the direct injection system supplying most of the fuel

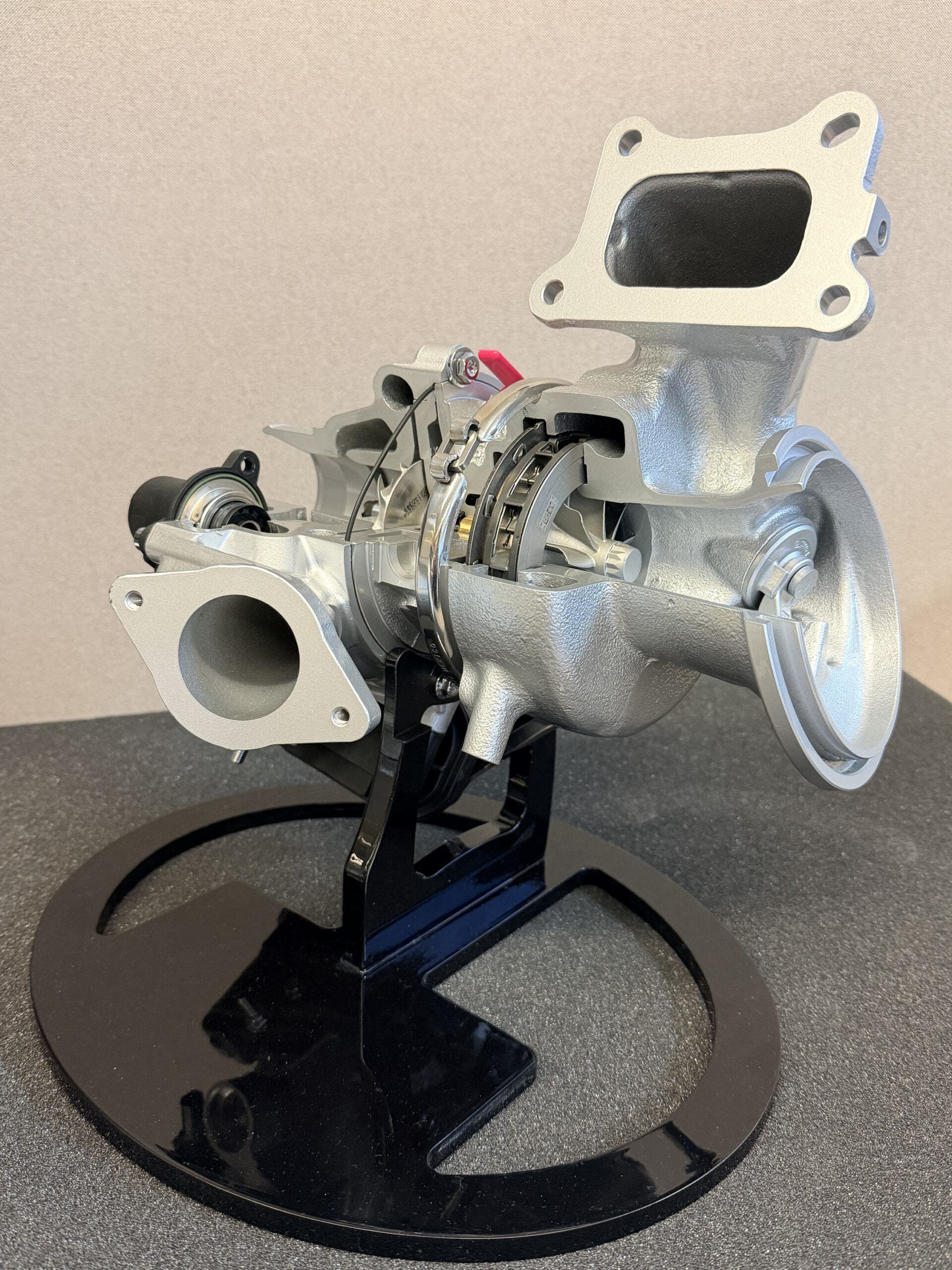

Boosting the performance of the Hurricane 4 Turbo is a variable geometry turbocharger with active vanes inside the housing, delivering up to 35 psi (2.4 bar). It provides significant low-end boost for power and torque during takeoff, acceleration, and cruising, with 90% of maximum torque available between 2,600 and 5,600 rpm. The pressurized air from the turbocharger passes through a liquid-to-air intercooler on its way to the engine, reducing the temperature for a denser and more powerful intake charge into the combustion chamber.

The variable geometry design allows Stellantis engineers to achieve high power density without compromising low-end torque and transient performance, while keeping the overall package compact compared to a conventional twin-scroll turbocharger.

Further improving engine efficiency, the Hurricane Turbo 4 uses an electric water pump and a variable displacement oil pump to reduce parasitic losses.

Solidity on a solid foundation

A die-cast aluminum block with a deep skirt provides a solid foundation for the Hurricane 4 Turbo. The single-piece casting is made by Stellantis, which also produces the oil pan and timing cover from die-cast aluminum.

The structural rigidity of the engine has been improved to minimize NVH (noise, vibration, and harshness). The Hurricane 4 Turbo features thicker cylinder bore walls (24% thicker than the current 2.0-liter DOHC I-4) and larger main and connecting rod bearings on the crankshaft. A structural bypass tray and balance shaft assembly are mounted in the lower part of the engine. A viscous crankshaft damper helps reduce vibrations.

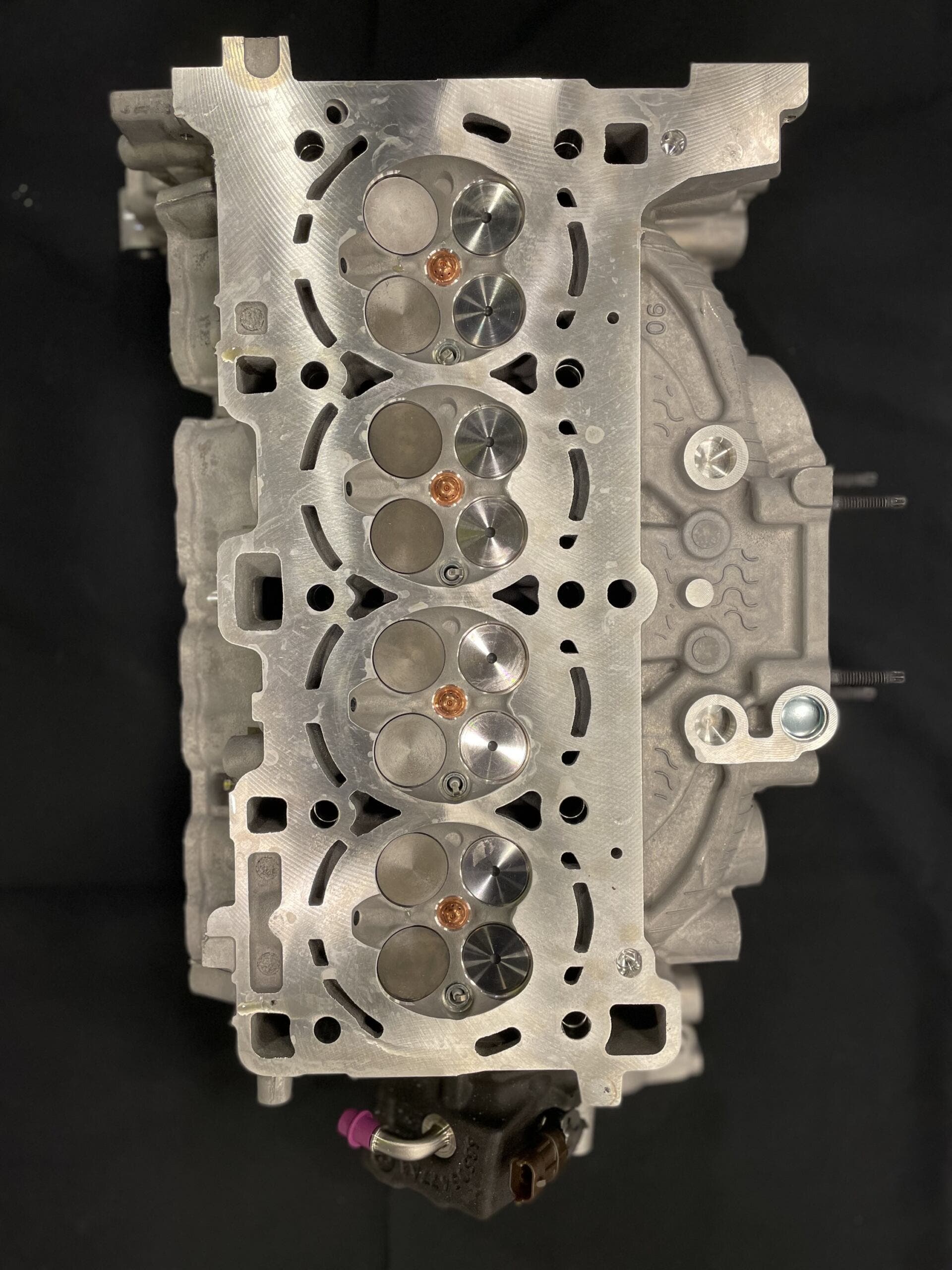

The aluminum head contains four valves per cylinder and overhead camshafts. The TJI chamber is press-fit into the center of each combustion chamber for easy assembly. Variable intake timing is quickly adjusted by an electric camshaft phaser, ensuring smoother starts. The exhaust valves are filled with sodium for heat management.

Just like Stellantis’ award-winning Hurricane Twin Turbo I-6 engines, the Hurricane 4 Turbo features an ultra-thin, low-friction PTWA (Plasma Transfer Wire Arc) coating in the cylinder liners. Compared to conventional iron cylinder liners, the PTWA coating offers 10 times greater wear resistance.

The PTWA process, borrowed from the aerospace industry, melts steel alloy wire at 2,300 degrees Celsius (4,150 degrees Fahrenheit), producing microscopic particles that are sprayed onto the cylinder walls at high speed, where they cool rapidly to form the coating and create a physical bond with the bore. Surface grinding gives a superfine cross-hatch pattern with controlled microporosity for oil retention. The spraying process leaves more aluminum between the cylinders, improving heat transfer and engine cooling.

The Hurricane 4 Turbo is assembled in Dundee, Michigan, with production to be added in Kokomo, Indiana, in the future. The aluminum block is cast and the bore coating is applied at Stellantis facilities in Kokomo, Indiana.